Nuecomer

Welcome Newcomer!

We have design this website in such a way, that even if your totally beginner or somewhere in between, you immediately pick up along the way.

As for the first timer, we recommend you to read the whole way through. it won't take more than 10 minutes.

as for returning customer, seeking specific info, we've place a jump start menu to save some time searching.

The Right Material..

Taking about Fabric Material, dating from predates until now (world wide) there's at least 300 types of cloth.

they are differentiates by how they're made (woven or not), types of knitted, absorbent range , material content, color combination,

harvesting technique, harvested location and lastly the designated purpose or designated (group / person).

as we wont's be covering such much ground, please click into designated link For more info...

Simple it may be, there are basically few Golden Rules that to be follow as in why "this" material is chosen for designated purpose.

- Durable

the idea of a bag is (to-carry) which is a break down into "how durable can it be? does it serve its purpose?".

A bag has to be durable enough to serve its purpose and more to increase its life cycle. - Customizable

the second idea is that the bag has to have the ability to be customize in such a way that it would be able to convey a message.

the message could be translated as an image of a product or a just a simple wording. as there are few way to do that, the most favorite

option is to print. Keep in mind that not all fabric is printable and some could end up in disaster.

Few problem with printing (too "hairy", too stretchable, loose waving pattern and surface just isn't flat enough). - Price-Wise

and the last one, pretty straight forward, it has to be price wise.

the main idea is always consist of those 3 points. the priorities might be different from one to another.

as foretold, without doubt, here are the list of materials that could accept all the essential requirement.

*this pages is intended for educational purpose only. Chloé Totebag does not claim to own the image, Some of the image belong to their respective owners.

NonWoven

Nonwoven fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted.

To be precise, it's plastic material, or Polypropylene (PP). In a bigger picture, it's currently leading material in terms of hygiene. as a reference, its famous for baby diapers, sanitary napkin, tampon, gowns and caps for surgery, pillow case and many more.

the characteristic of Nonwoven is its constant flat surface and very minimum stretch, which technically makes it the ideal material for textile printer or silk screen. Since it's PP, it is safe to say that water resistant, a good option for any outdoor activity.

Nonwoven came with a wide selection of thickness (GSM) and Color.

80 , 100 and 120 is the most common thickness use (GSM)

Polyester

High tenacity and good durability makes polyester the choice of fabric for high stress outdoors use. Polyester is also a strong fiber that is hydrophobic in nature. It is thus ideal for bag to be used in wet and damp environments.

Since the good trade of polyester, over the passing years, people tried to mixed cotton with polyester. Resulting most clothes is now is a combination of Polyester. t

he standout character in Polyester were water-resistant, wrinkle resistance and a good insulation. although some Polyester fabric proven to be problematic

when they are being woven/knited loosely, others work just as fine.

Most Polyester nowadays came with a combination with Cotton. a lesser variant of color if compare to Nonwoven, but have the advantage of a constant availability of the product on the market.

Cotton

Cotton fabric is the most popular fabric in the world. It's simply because it’s easy to care for and comfortable year-round. In hot, humid weather, cotton “breathes.”As the body perspires, cotton fibers absorb the moisture and release it on the surface of the fabric, so it evaporates. In cold weather, if the fabric remains dry, the fibers retain body heat, especially napped fabrics. It does wrinkle easily and is prone to shrinkage; however, blending cotton with other fibers and permanent fabric finishes reduces wrinkles and shrinkage.

Functional finishes, such as durable press and mildew-, flame- and stain-resistance, have added to cotton’s appeal. Even with shrinkage control, most cotton fabrics shrink during the first wash, so it’s imperative to prewash them before sewing.

When polyester is added to cotton, it doesn’t breathe well and tends to pill, so many consumers prefer the comfort of 100% cotton.

From a bag maker perspective, Cotton is very-very absorbent to water. In addition it's also wrinkle easily, which makes less attractive from a marketing point-of-view if you wish to put some advertisement or such.

On the other hand, its also could be clean easily (mean longer life time) and the feeling (touch) is very comforting even as a bag, which is the main reason of high demand of 100% cotton is still considerably high, despite its high cost. Bottom line, Cotton has a big portion on the market.

Our Natural Cotton 100% come with 100 and 130 Thickness.

Canvas

Canvas is an extremely durable plain-woven fabric used for making sails, tents, marquees, backpacks, and other items for which sturdiness is required. It is also popularly used by artists as a painting surface, typically stretched across a wooden frame. It is also used in such fashion objects as handbags, electronic device cases, and shoes.

In short, Canvas is combination between Cotton and Linen material. the "flax Stem" from linen material makes it more stiff, in other words more durable compare to others. thus the price. making it more essential for a more long term use, compare to the other material.

as you can see that Canvas material feels "some what" thicker than Cotton, but feels like Cotton.

the material is highly absorbent to liquid, thus waxing should be a compulsory for preservation.

…with the RIght Printing Methods….

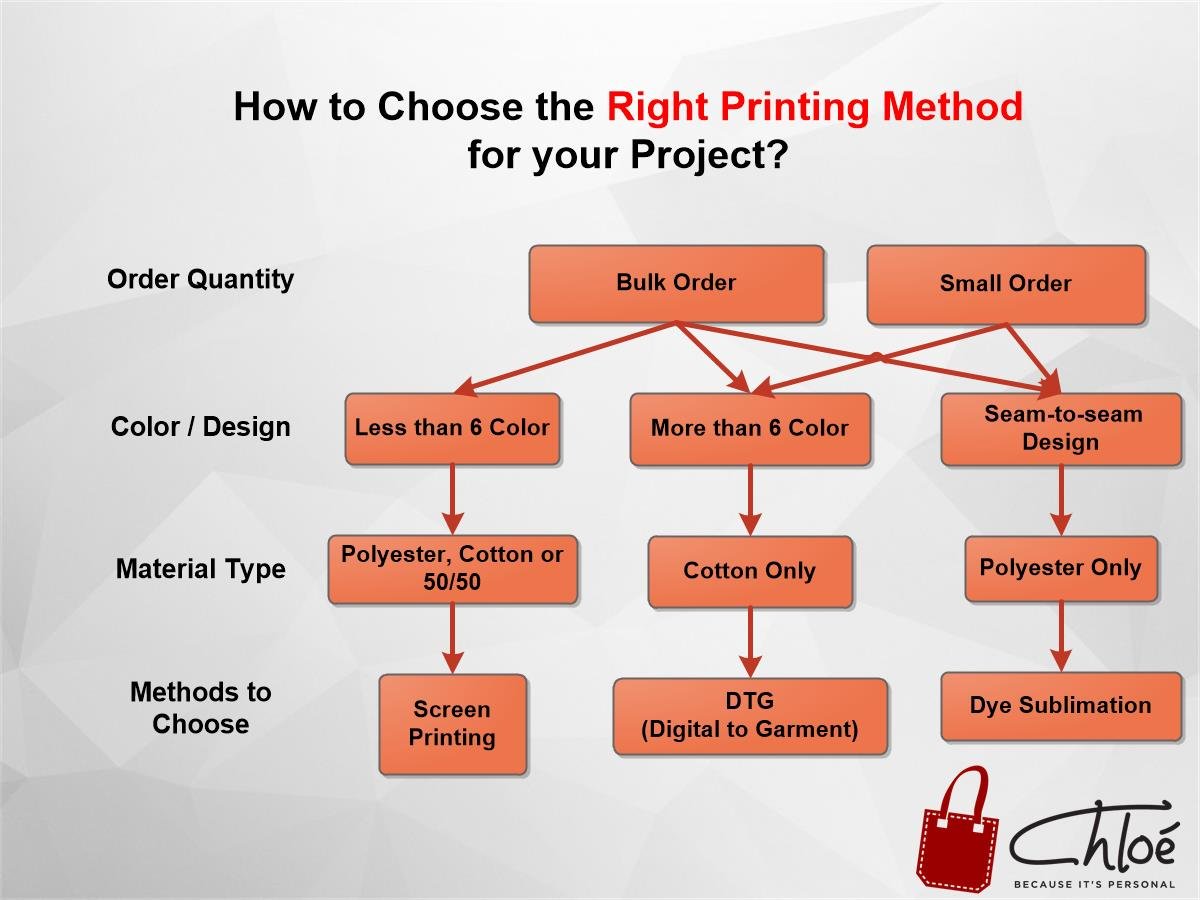

With the basic principal applies here also, we found out that the there are 3 ways to printout your bags.

- Screen Printing

- Dye Sublimation

- Direct to Garment

Here are some video we manage to find, to get yourself a better understanding of the methods we use,

and how does it actually work.

please note that the majority of the video upload were originally T-shirt printing purpose. however we can

ensure you that these process are the same with our production process

please keep in mind that there are few do's and don't regarding this which will be cover on their respective class.

And with the right choice, you could save both TIme and Money.

*this pages is intended for educational purpose only. Chloé Totebag does not claim to own the image or Video, Some of it belong to their respective owners.

Screen Printing

Screen printing is a printing technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. More info on wiki

Dye Sublimation Printer

A dye-sublimation printer is a computer printer which uses heat to transfer dye onto materials such as a plastic, card, paper, or fabric. These are not to be confused with dye sublimation heat transfer imprinting printers, which use special inks to create transfers designed to be imprinted on textiles, and in which the dyes do indeed sublimate. These are done at lower temperatures but higher pressures, particularly in all-over print processes. More info on wiki

Direct to Garment

Direct to garment printing, also known as DTG printing, digital direct to garment printing, digital apparel printing, and inkjet to garment printing, is a process of printing on textiles and garments using specialized or modified inkjet technology. The two key requirements of a DTG printer are a transport mechanism for the garment and specialty inks (inkjet textile inks) that are applied to the textile directly and are absorbed by the fibers. More info on wiki

Conclusion…

Each of these method has a very unique and specific ways of printing, resulting in need of specific material.

which of course, with different material making the end product is simply incomparable to one another.

for example, by using a Dye Sublimation means that you will used Polyester material. or by using Direct to Garment also means that cotton will be used. the big major factor it self, that is polyester and cotton is different in many ways such as texture, strength, lifespan, feel and cost.

Clearly with Dye Sublimation and Direct to Garment, the quality is impressive but sadly its parallel with the cost.

for those user whom more budget concern and looking for rather more practical bag in term of usage than in design,

Screen Printing is a more suitable choice.